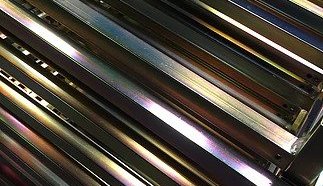

Zinc Plating

Zinc plating (Macdermid Kenlevel Acid Zinc)

Zinc plating is a is a form of cathodic corrosion protection, due to its electronegative properties to iron, this is where a deposit of zinc is plated onto a substrate, and corrodes preferentially to this, thus extending the life of the part underneath.

Acid Zinc is a bright Zinc deposit, so as well as the desired corrosion protection it also has a great aesthetic appearance, which can be further altered with passivates to enhance the protection and appearance of the part.

Zinc + Trivalent passivate processes

Parts processed through the tripass process are REACH,RoHS,ELV compliant being free from hexavalent chromium, strong complexors and cyanide.

Zinc + Hexavalent passivate processes

Parts processed through our hexavalent systems obtain excellent corrosion resistance as they have a hexavalent chromate layer, this layer allows the deposit to self heal if damaged or scratched due to the chromate layer re-passivating affected areas.

Trivalent Clear passivate

Trivalent thick film passivate

Hexavalent Gold

Hexavalent Black

Hexavalent Green/olive (barrel only)

With Barrel&Rack lines, we can process a large range of parts in all sizes and quantities.

Zinc-Nickel

Rack (Macdermid Enviralloy Nispeed 12-15%)

Barrel (Enviralloy 12-15%)

ELV Reach&RoHS compliant (Trivalent).

Zinc-Nickel plating, like Zinc is a form of cathodic corrosion protection, however the deposit that is put onto the substrate is an alloy of Zinc and Nickel in a ratio of 85-88% Zinc and 12-15% Nickel, this specific range of alloy gives much better corrosion protection from less deposit than Zinc, and is able to reach 1000 hours salt spray from only a 10 micron deposit.

Other benefits of Zinc Nickel are that it has the best abrasion resistance of all zinc alloys, improved ductility, resistance to high temperatures and also an excellent plating/alloy distribution.

Zinc-Nickel is a great replacement for toxic metal Cadmium.

Trivalent Zinc Nickel; parts processed through our tripass process are REACH,RoHS,ELV compliant being free from hexavalent Chromium, strong complexors and Cyanide.

Clear passivate

Black passivate + Relubro 80 topcoat

We also offer a hexavalent Gold passivate finish to adhere with certain industry standards such as the oil&mining industries.

JW Rudge are National grid approved suppliers.

With our Rack&Barrel plant running efficiently with Macdermids enviralloy processes, we are able to offer a quick turnaround with a consistent bright alloy finish.

Tin Plate

Tin plating is used for a multitude of reasons and across many industries, it is corrosion resistant and also resistant to adhesive wear, also non-toxic and FDA approved for food industry standards.

Tin is used largely in the electronics industries beacuse of its properties such as, Excellent Solderability, Good electrical resistance, and will plate on ferrous and non-ferrous metals (e.g.Copper) for connectors etc.

Here at JW Rudge we offer bright&dull tin for both rack&barrel for processing parts of all sizes/quantities. We also offer tin plating on Aluminium using a pre-plating seal which allows Tin to be deposited.

Topcoats / Lubricants

We have a range of topcoats for finished products that can extend the protection/shelf life products or attain desired properties like lubrication.

-PS100 (passivate sealer) topcoat that acts as a seal to protect the passivate and increasing the corrosion protection(Rack & Barrel Zinc).

-HydroKlad SC40 (lacquer) this lacquer drys and leaves a film on the parts, protecting the parts&passivate even further and greatly improves the salt spray hours achieved (highly recommended).

(Rack Zinc & Zinc-Nickel only)

-Torque 'N' Tension (reccomended for parts with neccessary friction properties) (Barrel only)

-Relubro80 (Zinc-Nickel Rack & Barrel only)

-Finigard 460 (lacquer) this organo-mineral solution which drys and leaves a film on the parts, protecting the parts&passivate even further and greatly improves the salt spray hours achieved (highly reccomened) (Zinc & Zinc-Nickel Barrel only)

Other Services Stainless Steel Passivate Stainless steel is corrosion resistant by design but not completely un-susceptible to it, our stainless steel passivate is made to remove any surface contamination of Iron and leave a less chemically active film on the substrate to further reduce susceptibility to corrosion We offer this for barrel processing only. Hydrogen de-embrittlement Due to the nature of electroplating and its requirements Hydrogen embrittlement is very common, especially when acid pickling and plating, Hydrogen atoms are induced under the surface of the metal and can cause metals to become brittle and cause unpredictable fractures, also known as HIC(Hydrogen induced cracking) Jw Rudge has therefore invested in an oven designed for Hydrogen de-embrittlement, this allows us to relief bake components wih high tensile strengths to prevent Hydrogen damage. depending on the specification and properties of the substrate this can take between 4-22 hours. XRF Testing Services Our XRF is used to accurately read thicknesses of deposits, ensuring compliancy and consistency. It can be used to measure alloy composition where neccessary or idenitfy materials.

Nickel, Chrome & Anodise

Here at JW Rudge we offer bright nickel and chrome plating, nickel itself is a bright aesthetically appealing finish, it is a very hard wearing, low porosity, low friction anti galling material.

- It combines Corrosion resistance, and excellent thickness distribution and hardness of up to 600 Hv.

- With a similar appearance to chrome, a bright mirror finish and no need for polishing it is ideal for car/motorcycle restorers and DIY enthusiasts

Chrome

Chrome is generally desired for its mirror like appearance, obtaining up to a 100% reflective finish.